Electronic components are everywhere. From small resistors to huge power supplies, they are a fundamental part of how we design and build electronic equipment. But what happens when you come across a counterfeit electronic component?

When the word counterfeit is thrown around, one of the last things that may come to mind are electronic components. In everyday life, people associate counterfeit with money or high-end goods, but there is an entire world of electronic component counterfeits that have infiltrated many industries including automation, medical, and aerospace and defense.

Electronic components that have been intentionally duplicated, altered, or fabricated to falsely imitate genuine components are known as counterfeits. These components are designed to look exactly like authentic parts but often have major differences that can affect their performance and reliability. The attempt to pass off counterfeits components as authentic can involve changing the part numbers, repackaging, or even mixing them in with lower-quality components.

Counterfeit electronic components can be a real problem for electronics manufacturers. These fakes are often made with cheaper materials and less care than their genuine counterparts, making them unreliable and potentially dangerous. If the counterfeit component fails to function properly or break, problems with safety and product performance will result in improper operation of the product it is used in, which would lead to indirect harm from the counterfeit part. These malfunctions will cause issues with product performance and increasing safety risks, leading to massive problems and complications.

Counterfeiters target companies of all sizes, but they’re especially likely to target larger companies that buy large volumes of products from multiple suppliers or distributors, and those tend to be big companies with significant budgets for purchasing equipment and supplies. Smaller businesses may not have the resources to verify every single purchase against “trusted” sources, so they’re more likely than larger ones to end up with counterfeits by accident.

It can be difficult to detect counterfeit electronic components because they are often indistinguishable from genuine ones at first glance. However, there are several ways that companies can protect themselves against counterfeits. Here are three solutions on how to combat counterfeit electronic components.

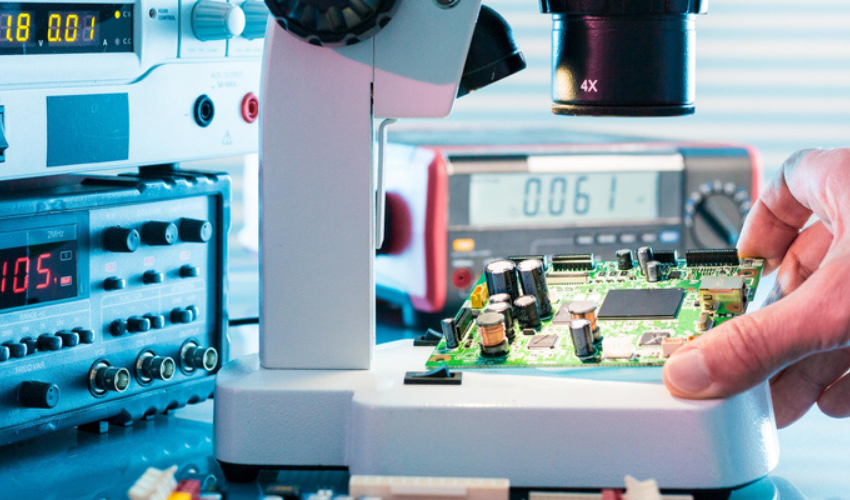

One of the easiest ways to identify counterfeit electronic components is by doing a visual inspection of the part. Counterfeits can look as if they have bent leads or have been reworked or sanded. Often times, counterfeit manufacturers cannot replicate the markings on the part such as font, spacing, logos, or misspelled part names and numbers. A skilled inspector can use an optical microscope to do a visual examination of the part and quickly catch the inconsistencies. An x-ray can be done to get an internal look at the component. This inspection can determine if a part has missing or broken wire bonds or if anything inside the component is inconsistent with the authentic part.

Look for markings and certifications to find out if components are counterfeit. Some manufacturers include serial numbers or other identifying markings on their products as part of their quality control processes. These certifications show that the component has undergone testing and complies with established performance and safety requirements. Maintaining brand familiarity with well-known manufacturers’ brand marks helps in maintaining visual quality control of any incoming inventories. If you suspect that your company has received counterfeit parts, check these markings carefully. They will help determine whether the components are legitimate or counterfeit.

Purchasing from certified distributors is one of the best methods to guarantee you receive authentic electronic components. These distributors are more likely to stock authentic components since they have a direct connection to the manufacturers.

Area51 Electronics is both an authorized and independent distributor, offering the best of both worlds. As an authorized distributor, we work directly with the OCM, guaranteeing your part comes directly from the manufacturer. This ensures you have authentic parts purchased directly from our authorized sources.

And as an independent distributor, we offer certifications and a rigorous quality management systems process (QMS). Two important certifications to look out for are AS6081, which offers guidelines for evaluating and mitigating suspect components, and ISO 9001, which addresses the standards for QMS.

Area51 Electronics is certified in both AS6081 and ISO 9001 and are members of SAE G19D committee, that have set the standard for counterfeit mitigation in the electronics distribution industry since 2013. Area51 Electronics is dedicated to maintaining the highest standards in the detection, avoidance, mitigation, and disposition of counterfeit electronic components.

Area51 Electronics conducts comprehensive counterfeit mitigation from our in-house, cutting-edge quality assurance and testing facility in accordance with our QMS. Our team has equipment to identify, reduce, and avoid suspect and counterfeit parts. We apply a risk management process that involves visual inspection, various test methods, and accurate reporting.

An authorized and independent distributor removes the headache of jumping from one distributor type to another. Everything being done in one place means clients can focus on growing their business and maximizing productivity.

Area51 Electronics has everything you need to reduce the risk and combat counterfeit electronic components in your supply chain.