On March 16th, 2022, a 7.4 magnitude earthquake struck off the coast of Japan’s Fukushima prefecture. The quake cut off power to millions of people, according to a report by CNN, with over 100 people injured and 4 killed. A tsunami warning was put into effect but lifted Thursday morning after no abnormalities were detected at any of Japan’s nuclear plants.

The fears though, have yet to abate. 11 years ago Japan was rocked by a 9.0 earthquake that resulted in a massive tsunami with waves reaching 133 ft. This tsunami caused the Fukushima Daiichi nuclear disaster with meltdowns of 3 prominent nuclear reactors. March 16th’s earthquake has sparked concerns over a similar disaster.

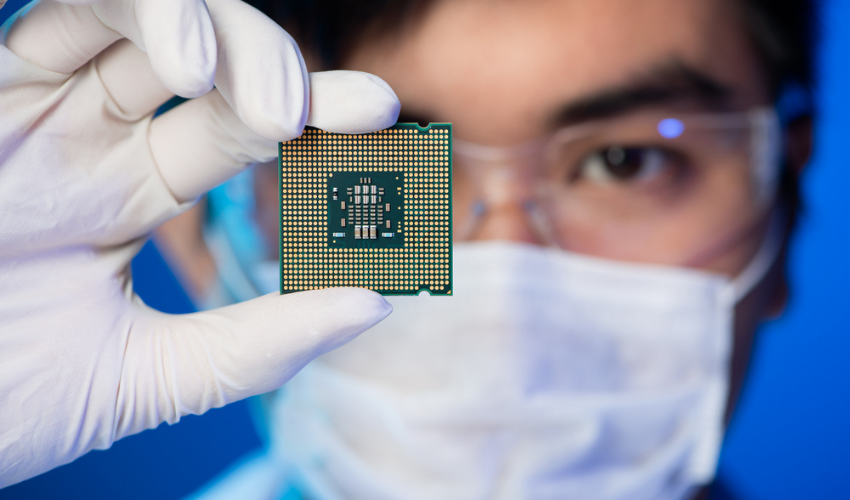

Renesas Electronics Corp., a semiconductor manufacturer for the global automotive industry, is not taking chances. After suspending operations at Naka, Takasaki, and Yonezawa factories near the quake zone, it is unclear when production will resume. Renesas said partial production has resumed on certain lines at the Yonezawa plant, which produces microcontrollers for automotive and industrial use. Only two of the plants have had their power restored.

Even if there is no damage, Renesas said production will take several days to completely restart factory facilities. The Naka plant, also used for the production of microcontrollers, suffered a devastating fire on March 19th, 2021 almost a year to the day. Renesas Electronics Corp. is responsible for almost a third of the global market share of the microcontroller supply used in the automotive industry.

Last year’s fire at Renesas’ Naka plant, exacerbated by Texas snowstorms that put American manufacturers out of production, worsened the already strained global supply chain. While the earthquake might not have caused major damage to Renesas’ three plants, the number of setbacks to the global supply chain is.

The ongoing war in Ukraine has contributed to a climb in prices from food to gas. In regards to semiconductors, Ukraine is responsible for 50% of the world’s supply of neon gas, used to produce chips. China is facing new lockdowns in the face of rising Covid-19 outbreaks. These disruptions could prove enough of a chokepoint to extend the semiconductor shortage another year.

Despite the setbacks, experts believe the impact of the earthquake on the global chip shortage will not be severe. Damages appear minimal with short production stalls expected as inspections are scheduled for the suspended plants. It’s important to keep an eye on the news and market demand with these disruptions, as it doesn’t take much to cause a bottleneck on an already strained supply chain.