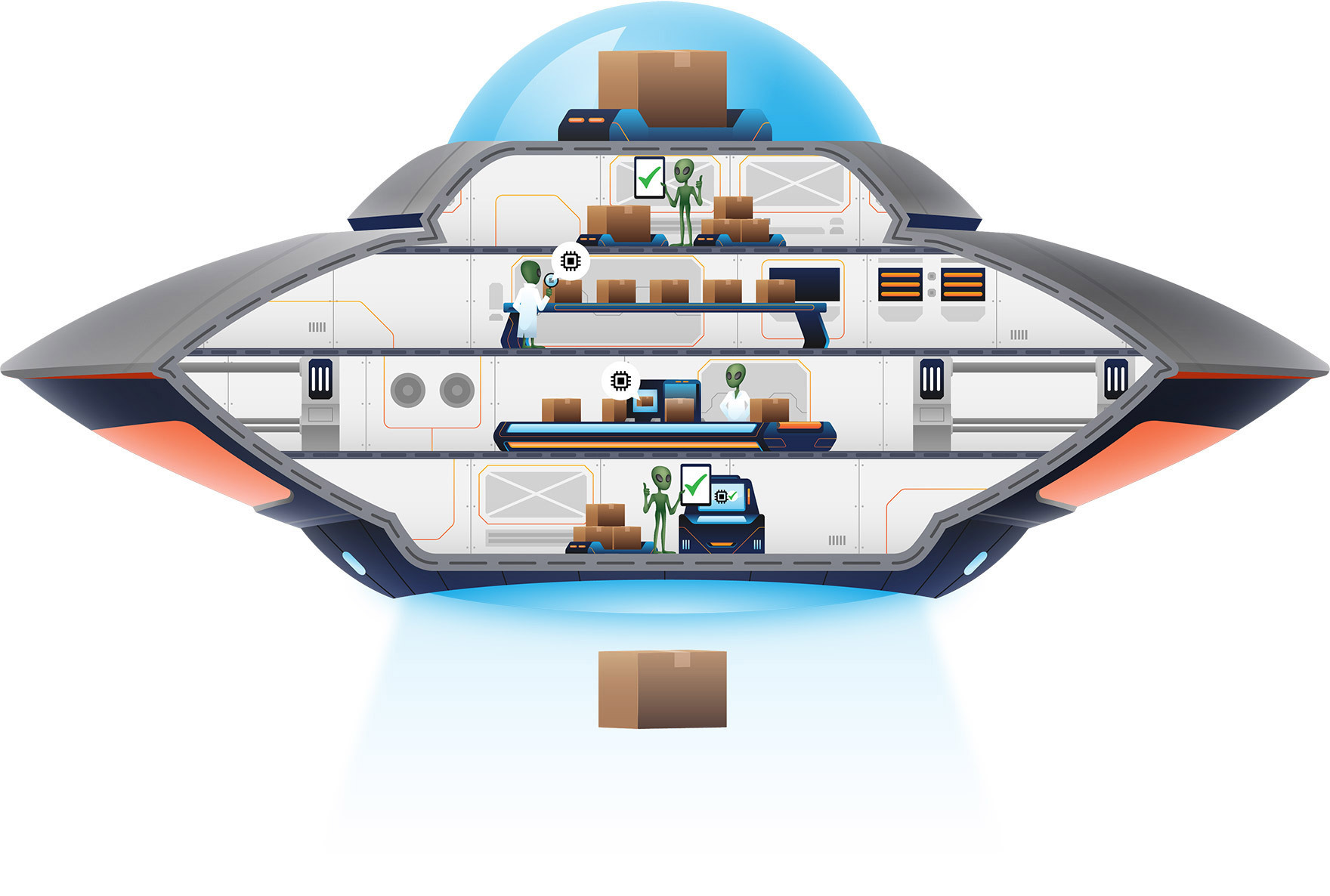

The electronic parts and components we supply are used in important applications that power innovation and drive technology. Our electronic parts are used in various applications from common commercial products to high-grade military, defense, aerospace, and space applications. That’s why we practice the highest level of quality assurance and counterfeit mitigation standards in the industry. Our large inventory of obsolete parts and hard-to-find components go through verification and rigorous lab testing. Here’s a glimpse into our inspection process from start to finish. For more details on each step, hover over the numbers in the orange circles under the UFO illustration below.

We believe the smallest things can make the biggest difference. We care about the people who depend on our products and services, and every component we distribute. Our quality team, processes, and technologies enable us to consistently distribute conforming products and services that meet our customers’ requirements. Our quality management system (QMS) meets the highest standards for testing and inspection and is certified to AS9100D, AS9120B, AS6081:2012, ISO9001:2015, and ANSI/ESD S20.20-2021. We are also FAA AC 00-56B certified. This system is followed throughout our organization to ensure operational efficiency and consistency.

We go to the ends of the earth to provide the highest level of quality and reliability in our products and services. That is why we’re committed to exceeding industry standards in all our internal operations. Our commitment to quality is the heart of our business and what makes our customer service out-of-this-world.